|

Kimpton Flooring

Are the leading specialist in lining clean rooms with

flexible sheet vinyl. We are a well established friendly company which

offers a professional service to many leading

Pharmaceutical Manufacturers, Research Laboratories and other end users that

require very durable, sterile, easy clean surfaces which will not crack,

flake or chip as is often the case with more expensive solid laminates,

plastic cladding, paint

and resin coatings.

The 2mm thick sheet vinyl cladding is available in various grades to

suit all requirements, including fire retardant to BS476 class ‘O’,

flame spread, anti-static for electronic production facilities and

slip-resistant for wet areas. The sheet vinyl is specially produced with

reduced flecking, no surface polish and added fire resistance.

Kimpton Flooring

Perfected

the method of fully coving Floors, walls and ceilings of Clean rooms and

then applying 2mm thick, 2 metre width, heavy duty Flooring grade sheet

vinyl, to the ceilings and walls of new and existing clean room areas,

the forming of the vinyl around all coved corners and using a

contrasting colour vinyl on the floors. All seams, joints and

mitres are then thermo-welded with matching vinyl welding rods which are

cut and smoothed flush so as to give an impervious surface all over. The

finished product is bright, easy to clean and will enhance any working

environment.

The fully flexible 2mm thick sheet vinyl cladding is

also

the ideal solution for lining Walls, Floors and Ceilings in Wet rooms,

Shower areas and commercial Kitchens as all seams and joints are

completely thermo - welded sealed against moisture and bacterial ingress. |

Detail showing safety flooring

coved up to meet flush with wall vinyl

With inset

thermo-welded 'shield' internal mitres

and flat edge welded

return external mitre. |

Kimpton

Flooring Offer a relatively low cost cladding solution

to Walls, Floors and Ceilings in clean room areas, as the sheet vinyl can be fixed directly over

standard tapered edge plaster boarding that only requires the joints taped

and skimmed flush. The plasterboard can be fixed directly over existing wall and ceiling

finishes without the need for costly paint removal and re-plastering.

Alternatively, the plaster board can be

fixed as a double layer over standard Gyprock type galvanised stud work which enables services and pipe work to be run

inside the cavity behind the stud wall. This

method enables clean rooms to be renovated or installed without costly

down time waiting for block work and plaster to dry out.

Call our Technical department for further

details, specifications and installation advice on:

02920 866 222

2mm Sheet Vinyl Cladding to Walls, Floor and Ceiling in

Sterile Laboratory as Installed by Kimpton Flooring.

Note how vinyl sheet is clad around drop

down return air duct.

|

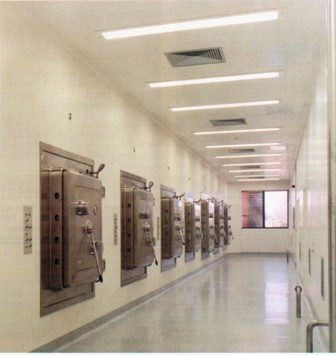

Main Autoclave area fully clad

in 2mm thick sheet vinyl

As installed by

Kimpton Flooring

London Blood

Laboratory, Elstree, Herts.

Click on image for details.

Major

project completed at London Blood

Laboratory, Elstree, Herts.

Kimpton

Flooring carried out and installed the single

largest clean room vinyl cladding project in the UK - The London Blood

Laboratory, at Elstree, Hertfordshire.

We installed over 40,000 square

metres of specially produced Flame retardant Gerflor 2mm thick, heavy duty

sheet vinyl was applied to Walls, Floors and Ceilings in Laboratories, Corridors,

Production and Storage Areas.

The flooring was thermo-welded to the wall

vinyl and all internal mitres on floors and ceilings were fitted with

separate 'Shield' type inserts to avoid single sharp corner joints that could

encourage a build up of grime.

Likewise, all external mitres were formed

around the sharp edge and thermo-welded on the flat side so as to make

much stronger, barely visible easy clean corners.

|